Recommended News For 3d Modeling Prague Mint Medals

Wiki Article

How Can High-Precision Cnc Machines Cut An Image Into A Master Hub, Or Die For Striking Gold Medals Or Coins?

CNC machines are essential in creating master hubs or dies that can be used for striking gold coins or gold medals. Here's a brief introduction to CNC Programming.

Computer-Aided Design (CAD) software produces a digital 3-D model of your medal or coin.

CAM (Computer Aided Manufacturing), software that generates toolpaths, instructions and commands for CNC machines using 3D models.

Choice of Die Material

The most durable and high-quality materials such as steel, brass or hardened alloys are selected to be used for CNC making the master hub or die. These materials can withstand high pressurizing processes and guarantee precise reproduction of designs.

Fixture and Setup

For precision To ensure precision, the material is fixed on the worktable of a CNC machine or vice. Proper fixturing is essential to stop any movement or vibrations during machining.

CNC Machining Process

CNC machines make use of cutting tools, for example end mills and ball mills to cut designs into the master hub or die.

The CNC machine uses the tools that are programmed, and removes the material precisely from the blank block of material based on the 3D specifications of the models.

Different sizes of cutting tools and types are used to create various dimensions, contours, and depths on the coin or medal.

CNC machine movement is controlled by computer algorithm, which ensures accuracy down to micrometer levels.

Finishing & Refinement

The master hub or die is refined further after the initial machine.

Surface finish can be obtained with the help of hand-polishing, or specialized tools.

Quality Control Inspection

The die or master hub must be inspected by using measuring tools like gauges or micrometers to verify precision and compliance with specifications of the design.

Hardening Treatment (Optional)

Certain dies can be heated-hardened or treated to increase durability and resistance to wear.

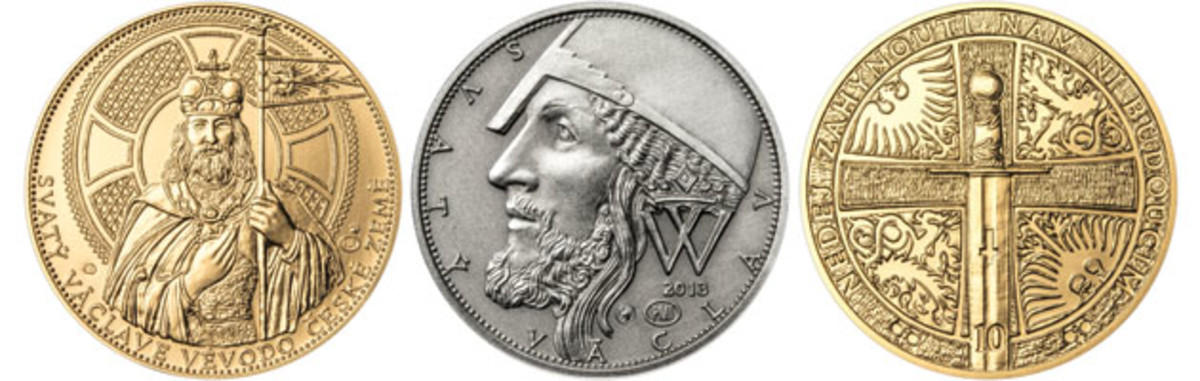

CNC machines can reproduce intricate designs on dies and master hubs with precision. They are crucial to make gold medals and coins with accuracy, consistency and fine details. Take a look at the recommended CNC Machining Czechoslovakia gold medals more tips including five dollar gold piece, gold penny, 1 oz gold coin, 100 gm gold biscuit, 50 pesos gold coin, american gold eagle, gold coin price today, sd bullion gold, silver double eagle, 1 oz gold buffalo coin and more.

What Can Laser Technology Do? Employed To Improve The Quality Of Gold Coins And Medals' Die Surfaces?

Laser technology is employed in the production of dies or master hubs for gold coins and medals to get precise details and to refine the surface to improve accuracy. Here is how the laser technology helps refine the surface during this process.

Laser technology is used to refine the surface of the hub or die after the initial cutting. It is able to smooth out imperfections and remove burrs.

Detail Enhancement-

Laser methods of engraving or ablation are employed to enhance or enhance the details of dies or master hubs. Lasers can be utilized to precisely etch and remove material. This allows for the creation of intricate patterns, fine lines or textures that are difficult to achieve with conventional cutting.

Microstructuring-

Laser microstructuring can create microscopic features and patterns on the surface of the die. This technique allows for the creation of specific patterns or textures that can improve the appearance and security features of coins and medals.

Surface Hardening and Treatment

In certain instances, laser technology is used for treatment or hardening of the surface of dies and master hubs. This process enhances the surface's durability and wear resistance, ensuring that the die or master hub can last a longer period of time.

Precision Changes

Laser technology is an exact way to modify or modify the die or master hubs without changing the geometry. It is possible to alter the surface of the die to fix imperfections, imperfections and other issues that could affect the quality of made coins or medals.

Controlled Material Removal

Laser ablation can be used to provide controlled removal of material, particularly in areas where complex details need to be defined or modified. The material is removed by contact, thus preserving the integrity of the area.

Laser technology is a great tool to enhance the appearance of dies and master hubs and master hubs, which result in more clarity, better surface quality, and increased accuracy. It is a complement to conventional machining processes, allowing for the exact manipulation and improvement of the characteristics of the die's surface crucial for making premium gold coins or medals. Have a look at the most popular laser processing Prague Mint gold medals more tips. including 24k gold coin, 2000 gold dollar, gold morgan dollar, old coins, 1 ounce gold, gold bullion, medal gold medal, ancient coin, silver eagle coins, gold eagle price and more.

What Is The Process By Which High-Quality Gold Blanks Get Weighed And Measured And Ready For The Minting?

This procedure is used to create gold-plated coins and medals that are of the highest quality. Here's the process and how it is carried outPreparation of the process Gold Material Selection High-purity gold is chosen to create blanks. Gold is refined to ensure that it meets the purity requirements for coins.

Gold Blank Production Gold material is cut into blanks by a blanking process. Blanking is the process of cutting discs or planchets that are the shape of coins out of gold with special equipment or stamping.

Accurate measuring and weighing

Weighing Every blank is weighed individually to ensure that it meets the specified specifications to be used for the coin. This ensures that every item contains precisely the amount of gold needed for the desired denomination.

Measuring. Instruments that are precise are used to measure the diameter, height, and the dimensions of every blank. This ensures uniformity and conformance to the specifications of the design.

Inspection and Quality Control

Visual Inspection- Each blank is examined visually to identify any imperfections on the surface, irregularities or impurities which could impact the overall quality.

Rejecting Blanks Which Don't Meet StandardsBlanks are rejected when they don't meet weight, size, or any other quality standards. This is done to keep the uniformity and uniformity.

Reasons for Preparation

Consistency in the Minting Process A precise measurement and weighed blanks ensure uniformity. Weight and dimensions are consistent, resulting in uniform striking of coins and medals.

Accurate Gold Content - Every blank is precisely weighed to ensure that the final coin, or medal, contains the exact amount of gold intended. This guarantees accuracy in terms of value and purity.

Preventing Variations - Uniform blanks prevent any variations in weight or size, which can affect the value of the medal or coin as well as its legality or capability to be used in commerce or circulation.

Quality Assurance – Strict controls on the quality of blanks during the preparation phase ensure that only flawless blanks are used in the minting process, reducing the chance of having flaws.

Legal Compliance - Uniformity and conformity to specifications is essential in coins that are intended for circulation or commemorative reasons, ensuring that they meet legal requirements and standards set by mints or regulatory bodies.

The accuracy and precision when it comes to preparing gold blanks of high-quality are essential steps in the process of minting, which ensures the production of precise, high-value, and legally acceptable gold medals or coins. Take a look at the top rated gold blanks for Czechoslovakia gold coins site examples including gold bars for sale near me, sell gold and silver near me, gold medal of olympic, order gold coins, gold bullion price today, gold coin shops near me, gold krugerrand, 1 ounce gold, today's 1 oz gold coin price, twenty dollar coin and more.

What Makes Gold Coins That Are Limited Editions Uniquely Numbered And In What Way?

For several reasons, limited editions, or collectible gold coins are usually uniquely numbered. They do this in order to verify authenticity, to make sure they are unique and to make them more appealing for collectors. This is how and why it's done.

Sequential Numbering: Every coin of a limited-edition or collectibles collection has an unique, typically engraving. This number represents a coin's place within the collection.

Certificate of Authenticity - The piece could come with a unique authentic certificate. This certifies that the coin is genuine. It contains information on the series, its metal content and minting.

There are many reasons to count coins by number

Authenticity Assurance - The individual numbering can be used to verify the authenticity of the coin in the restricted edition. Each number functions as a unique identifier, ensuring the coins authenticity. authentic and is part of the official collection.

Limited Edition Coins With individual numbers are considered to be more rare and exclusive. The fact that they are not available in a limited number of coins make them more desirable and desirable.

Coins with a Collectible Appeal have a collectible quality in that they allow collectors to keep track of and display specific numbers in the sequence. Lower or significant numbers within the sequence may be considered to be more desirable or desirable.

Individual Numbering - Collector Engagement increases interest and engagement of collectors in completing sets or acquiring specific numbers. Collectors can seek out particular numbers based on their preferences or goals.

Potential Value and Resell- Coins that have distinctive numbers can have more value, particularly when the serial number is less or if it's part of a desired series. These coins are prized by collectors because of their rarity, and they're uniqueness.

The ability to track and document a coin's history - Numerical coding helps in the tracking and documentation of a coin's past helping to prove its provenance and confirming it on the market for collectors.

Through the numbering of collectibles or limited edition gold coins mints, mints, or issuers, they establish authenticity, establish exclusivity and enhance the appeal of these coins to collectors seeking unique or important pieces. Numismatics appreciate these coins due to their unique significance. See the most popular Prague Mint gold medal numbering website recommendations including gold bullion bars, 1 10 oz gold coin, gold price jm bullion, bullion dealers near me, 1 4 oz gold coin, gold sovereign coins, 24k gold coins prices, sacagawea gold dollar, 1979 gold dollar, 1oz gold price today and more.